Inventory management comes with several challenges, including forecasting demand accurately and managing supply chain complexities. Artificial intelligence (AI) is transforming how businesses tackle these issues, particularly by helping maintain accurate stock levels, reducing costs, and improving customer satisfaction. This article examines the role of AI in inventory management and addresses the potential challenges businesses may face, along with the solutions they should consider.

Highlights

- Using AI in inventory management allows businesses to optimize stock levels, improve demand forecasting, and enhance overall operational efficiency.

- The main challenges of implementing AI in inventory management include high costs, complex system integration, and potential security risks.

Understanding AI in Inventory Management

AI in inventory management uses machine learning techniques to enhance various inventory-related processes. Although artificial intelligence cannot entirely replace humans in decision-making, quality control, and handling exceptions, it supports repetitive tasks such as data entry and order processing.

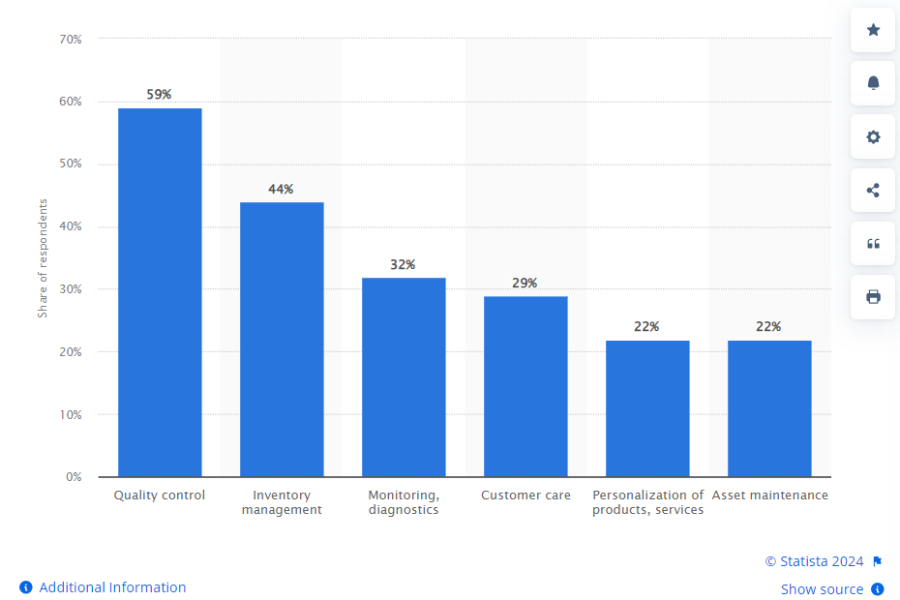

In this role, AI acts as a valuable assistant, enabling individuals to focus on more strategic, business-oriented tasks. In fact, within the manufacturing industry, 44% of respondents identify inventory management as the second most important use case for AI, following quality control.

The Advantages of Applying AI in Inventory Management

What advantages come from incorporating AI in inventory management? When applied effectively, AI offers substantial support that contributes to a company’s long-term success.

- Real-time data analysis: AI-driven inventory management presents real-time insights into stock levels, product demand, order status, operational performance, and customer experience. This capability enables business owners to quickly adapt to changing conditions and make well-informed decisions.

- Accuracy: Beyond providing instant access to necessary information, AI guarantees precision. Machine learning processes large amounts of data from various sources, identifying patterns that might be overlooked by humans. The algorithms continuously improve as they learn from new data and feedback, further refining their accuracy over time.

- Cost savings: As mentioned earlier, AI automates routine tasks traditionally handled by employees. In an ideal scenario, humans focus on setting inventory strategies aligned with business objectives, while AI handles the assigned tasks.

- Customer satisfaction: Customer satisfaction, and by extension loyalty, is a key benefit of AI-powered inventory management. Faster order fulfillment and responsive service help reduce instances where customers encounter out-of-stock items or face long delivery times.

Challenges and Limitations of Using AI in Inventory Management

Integration with existing systems

Integrating AI in inventory management systems presents a unique challenge, especially for businesses that rely on legacy systems. These older systems may not be built to communicate effectively with modern AI technologies, leading to compatibility issues. For instance, the data formats or software architecture of legacy systems may differ from the AI solution, requiring significant modifications or custom development to bridge the gap.

Moreover, integration often involves aligning AI-driven processes, such as predictive analytics and demand forecasting, with established workflows. This can be especially tricky if the business relies on manual or partially automated procedures. A custom integration might require creating APIs or middleware to facilitate the flow of information between systems, ensuring that data is transferred accurately and in real time.

Another important aspect is the synchronization of data between the AI solution and the legacy system. Discrepancies in data sets, such as outdated or incomplete inventory records, can undermine the effectiveness of AI algorithms. Therefore, a thorough data audit and cleansing may be necessary before integration. Testing the integration thoroughly in a controlled environment is crucial to minimize disruption to day-to-day operations.

Initial Cost

While AI can cut costs by automating tasks that would otherwise require human labor, the initial expenses of implementing AI in inventory management can be substantial.

For instance, the initial setup of an AI-driven inventory management system often involves significant costs, which can be particularly challenging for small businesses. These costs include purchasing or developing the AI software, integrating it with existing systems, and potentially investing in new hardware.

Beyond the initial investment, there are ongoing expenses to consider. Regular software updates, technical support, and system maintenance contribute to these ongoing costs. Small businesses, with their limited budgets, may find it difficult to absorb these expenses compared to larger enterprises that have more financial resources.

This financial burden can make it harder for smaller companies to adopt AI solutions, despite the long-term savings and efficiencies they might offer.

Security Challenges

AI handles highly sensitive supply chain and inventory data, making it vulnerable to security threats like cyberattacks and data breaches. To address these risks, one solution is to adopt strong cybersecurity strategies, such as regularly updating firewalls and intrusion detection systems.

For example, an eCommerce company managing large inventories can protect its data by implementing multi-layer encryption protocols. These encryption methods secure data both in transit and at rest, adding an extra layer of defense.

In addition, continuous employee training on security best practices and regularly conducting security audits can further safeguard the AI-powered inventory system from potential vulnerabilities.

Skilled Personnel

Roles such as data scientists, machine learning engineers, and AI specialists are essential to design, maintain, and improve these systems. The growing demand for these professionals makes it difficult for many businesses to find qualified candidates, particularly smaller organizations that may struggle with the cost of hiring talent in such competitive fields.

In many cases, businesses must either recruit new employees with specialized knowledge or invest in the training and development of current staff to manage AI technologies effectively. This upskilling process often requires extensive time, resources, and access to advanced training programs.

A company implementing AI in inventory management may need to train its IT department in machine learning algorithms and AI-based decision-making models. This could involve enrolling employees in specialized courses or bringing in external consultants. Without the right skill sets, AI’s full potential in improving inventory management may not be realized, which can limit the technology’s effectiveness and hinder business growth.

Data quality and availability

Data quality and availability are key factors for the effectiveness of AI in inventory management. AI models depend on accurate and timely data to generate reliable forecasts and insights. When data is inaccurate, incomplete, or outdated, it can lead to flawed predictions and poor decision-making, ultimately affecting inventory control and operational efficiency.

Maintaining high-quality data requires companies to implement processes like data cleansing, which involves removing duplicates, correcting errors, and filling in missing information. Data integration from various sources, such as sales, supply chain, and warehouse management systems, is another critical step.

Another common challenge businesses face is insufficient historical data for AI-driven predictions. Startups or companies entering new markets may need more years of data for AI models to learn patterns and trends. In such cases, businesses may need to explore alternative strategies, such as collaborating with third-party data providers or using synthetic data to fill in gaps.

Alternatives to AI for Efficient Inventory Management

While AI in inventory management offers significant benefits, it often comes with high costs, integration issues, and security concerns – challenges we mentioned in the previous section. They present a wall to access AI for many businesses, especially SMEs.

However, there are other advanced tools businesses can turn to in order to maintain operational efficiency without the complexities of AI implementation. ConnectPOS, for example, offers a robust inventory management solution that integrates seamlessly with both online and physical stores. With features such as real-time stock updates, multi-location management, and detailed reporting, businesses can streamline their inventory processes effectively. Currently, ConnectPOS is also working on integrating AI features to improve these capabilities further.

These advanced POS systems provide a more accessible and cost-effective way to optimize inventory, ensuring smooth operations and enhanced customer satisfaction without the hurdles that come with AI.

FAQ: AI in Inventory Management

- How does AI improve inventory management?

AI improves inventory management by providing accurate demand forecasts, optimizing stock levels, and automating routine tasks. For example, AI can analyze historical sales data and current market trends to predict future demand, reducing the risk of overstocking or stockouts. It can also streamline order processing and inventory tracking, improving overall efficiency.

- What are the benefits of using AI in inventory management?

The benefits of using AI in inventory management include enhanced forecasting accuracy, reduced operational costs, improved stock levels, and increased efficiency in inventory tracking and order processing. AI can also help businesses respond more quickly to market changes and customer demands.

- What are the challenges of implementing AI in inventory management?

Challenges include the need for high-quality and sufficient data, the requirement for skilled personnel to manage AI systems, and the cost of integrating AI technology. Businesses may also face difficulties in adapting existing processes and systems to work with AI solutions.

- How can businesses ensure data quality for AI in inventory management?

To ensure data quality, businesses should implement practices such as data cleansing, regular updates, and integration of data from various sources. Maintaining accurate and up-to-date data is crucial for the effectiveness of AI models.

- Do businesses need to hire new staff to implement AI in inventory management?

Not necessarily. While specialized roles such as data scientists and AI engineers are often required, existing staff can be upskilled through training programs and courses. Companies may also consider partnering with external consultants or AI service providers to manage the implementation process.

Conclusion

Successfully implementing AI in inventory management goes beyond just keeping shelves stocked. It’s about creating a responsive, data-driven system that aligns with the growing need for agility and precision in today’s supply chains. By leveraging AI effectively, businesses can strike the perfect balance between stock availability and resource optimization, reducing costs while meeting customer demand. As supply chain complexities continue to grow, businesses that prioritize smart, efficient inventory management will have a competitive advantage, positioning themselves for long-term success.

Ready to streamline your inventory management without the complexities of AI? Contact ConnectPOS today.

ConnectPOS is a all-in-one point of sale solution tailored to meet your eCommerce POS needs, streamline business operations, boost sales, and enhance customer experience in diverse industries. We offer custom POS with features, pricing, and plans to suit your unique business requirements.