Mid-market manufacturers face ongoing challenges in managing supply chains, particularly in predicting demand amidst shifting customer preferences and market trends. Traditional methods, often based on outdated data and intuition, struggle to keep pace. Modern demand forecasting aims to improve stock control, align resources, and enhance profitability. AI and Machine Learning are emerging as key tools in this shift, bringing precision to forecasting and supporting new approaches to inventory management. In this article, we’ll explore how AI inventory management software addresses the complex challenges mid-market manufacturers face in demand forecasting. We’ll examine how this technology minimizes waste, refines supply chain strategies, and helps businesses stay agile in an increasingly competitive market.

Highlights

- AI in inventory management allows businesses to accurately forecast demand by analyzing real-time data, past sales, and consumer trends, reducing supply chain errors by up to 50%.

- AI helps reduce waste by optimizing stock levels and automating dynamic pricing, ensuring businesses avoid overstocking and keeping products available at the right times.

Challenges with Traditional Demand Forecasting Methods

Demand forecasting is a complex task because customer preferences change rapidly. Social media trends, new product launches by competitors, and other influences can lead to sudden shifts, making future demand challenging to predict accurately.

While traditional statistical models provide a basic framework, they struggle to keep pace with the complexities of today’s market. For example, consider a fitness tracker that went largely unnoticed until a celebrity endorsed it. This endorsement could transform it into a must-have item, leading to a sudden spike in demand. Without adaptive forecasting, the manufacturer might find it difficult to meet this unexpected surge in orders.

This illustrates the need for more flexible forecasting approaches like AI inventory management software that accounts for unexpected factors like social influence and rapid trend shifts.

Benefits of AI in Inventory Management Software Forecasts Demand and Reduces Waste

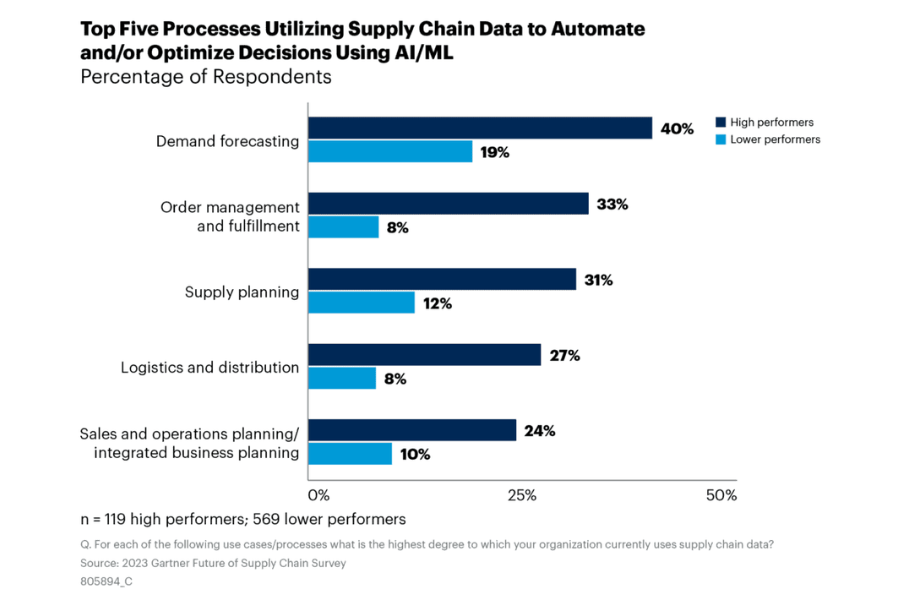

A recent Gartner survey of 818 supply chain practitioners conducted between August and October 2023 found that high-performing supply chain organizations apply AI and machine learning in their operations at more than twice the rate of lower-performing peers. These leading companies prioritize productivity as their central focus to drive sustained business growth, viewing it as more impactful than cost reduction or efficiency gains over the next three years.

This trend highlights the role of AI inventory management software to better forecast demand and reduce waste, supporting continuous operational improvement and forward momentum.

Forecasting Demand

According to McKinsey, organizations applying machine learning and AI-driven demand forecasting can cut supply chain errors by up to 50%.

AI inventory management software helps to cut waste by delivering insights into both large-scale and localized demand patterns. Through analysis of past sales, seasonal trends, and consumer habits, these systems are able to forecast demand accurately, so that each store receives the right product quantities. This approach minimizes overstock, prevents waste, and keeps products readily available for customers.

In the food sector, ordering decisions often rely on managers’ observations and limited data rather than broader demand insights AI could identify at a corporate level. Without full visibility into larger demand patterns, stores frequently end up with an excess of less-desired items or run short on popular ones, which can lead to significant waste.

Consumer goods benefit from similar AI forecasting systems that give planners insight into demand shifts. This helps them align stock levels with trends, especially for seasonal products, ensuring the shelves are stocked appropriately to meet customer demand.

Restocking Inventory

Automating replenishment and allocation tasks with AI helps businesses align product availability with real-time demand, cutting down on excess inventory and reducing the need for heavy markdowns to move stock. This synchronization allows stores to maintain the right level of stock without unnecessary waste.

AI inventory management software can handle complex replenishment needs across challenging product categories — from fresh, seasonal produce to newly promoted items. These systems account for demand influencers such as days of the week, pricing, promotions, holidays, local events, and even weather, allowing more accurate demand forecasting.

AI-driven replenishment removes the guesswork, setting inventory levels based on precise store-order projections. This approach also strengthens supply chain planning, aiding in resource allocation and capacity management by providing clear visibility into product flow requirements.

Markdown and Clearance Strategy

Retailers face a challenging balancing act with inventory: holding onto products too long can lead to both economic losses and environmental impacts, yet customers also expect swift availability. AI can play a transformative role in this arena, using dynamic pricing adjustments throughout a season to help products reach customers at optimal times. This approach keeps items moving before they lose appeal and prevents the usual post-holiday slump that often leads to waste.

Consider the example of Halloween. According to the U.S. Department of Energy, around 1.5 billion pounds of pumpkins are grown each year, with peak demand occurring between October and December. Unfortunately, only about 20% of these pumpkins are consumed as food, while the remainder usually end up in landfills. This presents a unique inventory challenge for retailers, who must carefully manage their supply to avoid a surplus that will simply be discarded.

AI inventory management software can assist in this process by adjusting prices and inventory levels based on real-time demand signals, helping retailers ensure they stock just enough pumpkins to meet customer interest without over-ordering. Through these automated adjustments, stores can reduce the risk of unnecessary waste while still keeping shelves stocked for the Halloween rush.

This intelligent approach to inventory management ultimately allows retailers to meet customer needs efficiently, without the economic and environmental costs associated with excess products.

Cooperative Supply Chain Management

Coordination between retailers and producers is essential in managing inventory effectively, especially for items with lengthy lead times, such as pumpkins, which require 90 to 120 days from planting to reach shelves. When forecasts and planned orders are communicated well ahead of time, the supply chain can adapt, lowering the chances of excessive production and reducing the potential for waste.

Suppliers contribute by providing ongoing, detailed updates about availability, constraints, and lead times, while retailers gain insights into supplier reliability and can make data-backed decisions about promotions and pricing adjustments. This two-way flow of information allows both parties to align their strategies for production and distribution.

With the support of advanced algorithms, accurate demand forecasting becomes possible, helping retailers and consumer goods companies fine-tune inventory levels and meet customer needs.

This AI-powered collaboration guides production and delivery, ensuring that each product reaches the right location at the right time. The result is a system that carefully balances supply with demand, avoids excess stock, and cuts down on waste, all while ensuring a dependable supply for consumers.

How ConnectPOS can Empower Your Inventory Management

ConnectPOS, a pioneering retail technology platform, redefines the shopping experience by integrating advanced capabilities to benefit both customers and retailers.

- Real-Time Stock Visibility: ConnectPOS is a custom POS that provides up-to-date inventory levels across all locations, helping retailers track stock movements and minimize out-of-stock situations. This ensures that products are available when and where customers need them.

- Cross-Platform Access: Manage inventory smoothly on any device, including tablets, smartphones, and desktops, allowing easy access to stock data for staff on the go or in-store.

- Automated Stock Replenishment: ConnectPOS supports automated reorder alerts based on real-time demand data, helping retailers avoid overstocking or running low on key items.

- Efficient Barcode Scanning: Instantly scan items using device cameras or scanners to check stock levels, validate orders, or update product details, streamlining stock checks and restocking processes.

- Improved Security for Inventory Data: Role-based access controls ensure that only authorized personnel can modify stock data, while activity logs track changes, enhancing data security and accountability.

- Digital Record Keeping: Automatically save purchase orders, supplier details, and stock movement records within the system, making it easy to review past data, manage returns, and handle supplier queries.

- Detailed Reporting and Analytics: Gain valuable insights into inventory turnover, product demand trends, and stock performance. ConnectPOS’s analytics tools help inform smarter ordering decisions, pricing adjustments, and promotional strategies.

ConnectPOS is developing advanced AI tools to help retailers predict demand more accurately, align stock levels with expected demand, and reduce waste from unsold inventory.

FAQs AI Inventory Management Software

- Can AI software integrate with existing inventory systems?

Yes, most AI inventory management software can integrate with existing Enterprise Resource Planning (ERP) systems, Point of Sale (POS) systems, and other business software. This allows for a more cohesive and unified approach to managing inventory across different platforms. - Is AI software for inventory management suitable for all types of businesses?

Yes, AI software for inventory management is scalable and can be used by various industries, including retail, food and beverage, manufacturing, and e-commerce. It can be customized to meet the unique needs of different businesses, regardless of size or sector. - Can AI inventory management software reduce waste?

Yes, AI helps minimize waste by optimizing stock levels. By predicting demand more accurately, businesses avoid overordering, which reduces the chances of excess stock expiring or becoming obsolete. - What are the costs associated with AI software for inventory management?

The cost of AI software for inventory management can vary based on the software provider, features, and customization options. Some software solutions offer subscription-based pricing, while others may charge a one-time fee. It’s important to consider the return on investment (ROI) through improved inventory accuracy and reduced waste. - What kind of reports and analytics does AI inventory management software provide?

AI-powered systems typically offer detailed reports and dashboards covering stock levels, sales performance, demand trends, order accuracy, and inventory turnover. These insights help businesses make informed decisions about ordering, pricing, and promotions.

Conclusion

Traditional forecasting methods often depend on historical data, making it challenging to adapt to rapidly changing markets. AI inventory management software incorporates a broader range of variables, paving the way for more precise and adaptive demand forecasts.

As the manufacturing sector moves toward data-driven forecasting, AI is set to transform how businesses manage inventory, control costs, and meet customer expectations. These capabilities are now foundational in today’s competitive landscape. Ready to explore how AI and ML can reshape your manufacturing operations? Contact ConnectPOS to learn about tailored demand forecasting solutions that cut costs and reduce waste, helping your business stay responsive and agile.