Unlock the potential of RFID inventory management solutions and see how they elevate efficiency and accuracy in modern warehouses. In South Africa, businesses are increasingly adopting RFID technology to facilitate operations and achieve real-time data accuracy. This transformative tool is revolutionizing inventory management, offering unparalleled benefits in tracking and operational workflows. Dive into the world of RFID in thí blog and discover why it’s becoming indispensable for businesses aiming to enhance their inventory processes.

Highlights

- RFID uses wireless data in smart tags to track items, offering real-time inventory levels and accurate stock counts.

- RFID streamlines inventory by automating data collection, reducing errors, and enhancing security and stock availability.

- Retail, healthcare, logistics, and manufacturing industries benefit significantly from RFID.

What is The RFID Inventory Management Solution?

Inventory management is integral to most businesses and involves sourcing, storing, and selling items. Inventory tracking is essential to estimating profits and restocking, and this is where RFID inventory management solutions come into play.

Radio-frequency identification (RFID) uses digitally encoded data in smart tags, employing wireless transmissions to track and identify items. This technology provides real-time access to inventory levels, accurate stock counts, and detailed order and purchase summaries.

RFID inventory systems significantly simplify the inventory process, enabling precise stock management by automating data collection and minimizing human error. With RFID, businesses can streamline their inventory processes and ensure better security against theft and loss.

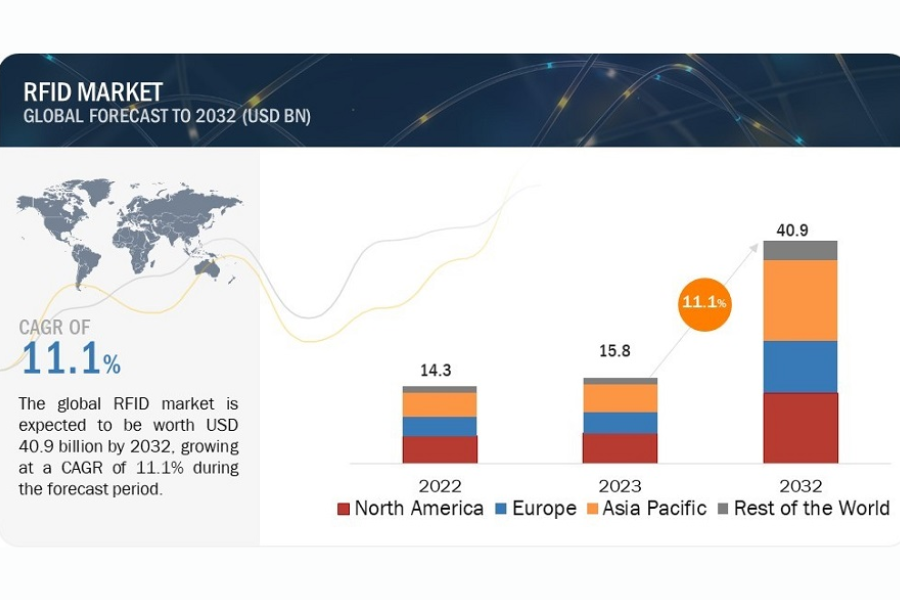

The market for RFID technology is expanding rapidly. According to a MarketsandMarkets study, the RFID market is projected to grow from $14.5 billion in 2022 to $35.6 billion by 2030, at a compound annual growth rate (CAGR) of 11.9%. This growth underscores the increasing adoption and importance of RFID technology in inventory management.

Advantages of RFID Inventory Management Solution in Retail

Tracking Real-Time Inventory

An RFID inventory management solution provides real-time tracking of products throughout the entire supply chain, allowing businesses to locate each item at any given moment precisely. This capability significantly reduces the risk of misplacement and loss, as each product is continuously monitored from the point of origin to its final destination.

By enforcing RFID technology, businesses can achieve a remarkable enhancement in inventory accuracy, with improvements of up to 300%.

Enhancing Product Tracking Through WMS Integration

Warehouse Management Systems (WMS) oversee the receipt, storage, and distribution of goods, maintaining data on inventory levels, product locations, reordering needs, and other crucial supply chain information. Integrating RFID technology with a WMS can streamline and improve product tracking.

When goods arrive at a warehouse, employees can use RFID scanners to scan and register each pallet in the WMS quickly. As products are stored, they can scan the item and bin number for precise location tracking. Furthermore, when items are picked for distribution, each RFID tag is scanned, marking the item as leaving the distribution center, making the tracking process faster, easier, and more accurate.

Boosting Product Handling Efficiency

RFID tags significantly enhance route planning and the handling of goods within and across supply chain locations. By tagging logistics assets like trucks, containers, and forklifts, employees maintain real-time visibility of these assets. This allows for quicker retrieval of equipment and products, improving transportation and logistics operations.

RFID technology integrated into inventory management systems helps streamline processes, cut delays, and improve the flow of goods, leading to better performance and cost savings.

Increasing Inventory Counting Speed

RFID tags and scanners significantly accelerate inventory counting and reconciliation.

Warehouse employees can use handheld RFID devices to quickly and accurately scan tags. Some scanners count each tag individually, while others can simultaneously tally all tags in a specific area. This faster and more frequent inventory counting leads to more precise inventory management.

Fixing Incorrect Inventory Counts

RFID inventory management solution simplifies identifying the sources of issues with receiving, storing, or distributing products. It allows warehouse employees to trace the movement of individual items and investigate discrepancies.

For instance, if an item is stored incorrectly, an RFID scanner may detect the tag in the wrong location and alert the user. Since warehouse managers have detailed information about the problem, they can be more active in taking preventive measures to avoid future issues.

Improving product availability

In today’s retail environment, customers expect products to always be available. By integrating consumer demand data with RFID’s real-time product tracking, suppliers can ensure that inventory levels are sufficient to meet demand.

RFID inventory management solution provides continuous visibility into the location of products throughout the entire supply chain. As a result, suppliers, manufacturers, and retailers can track products from production to the point of sale, ensuring inventory levels meet demand projections.

For example, if demand data indicates a surge for a particular item, RFID systems help suppliers quickly identify stock levels and replenish inventory as needed. This proactive approach maintains optimal stock levels, reducing stockouts and improving overall product availability.

Automating Product Receipt, Storage, and Distribution

Modern warehouses increasingly rely on automation to enhance efficiency in goods receipt, inventory storage, picking, and distribution. RFID technology significantly boosts these automated systems by enabling precise product identification, handling, and routing.

RFID tags on products enable robots to detect and manage items with accuracy. These tags assist robots in storing products in or retrieving them from specific locations. Moreover, equipment tags assist robots in efficiently using specialized picking and packing technology. Therefore, incorporating RFID with automation reduces dependence on human labor, potentially lowering operational costs and improving efficiency.

Optimizing the Manufacturing Process

RFID enhances the manufacturing process by lowering costs and increasing production speed while maintaining high-quality standards.

Suppliers can use RFID tags to track raw materials and components within their facilities. This capability reduces the likelihood of reordering misplaced parts, as lost items can be quickly located. Furthermore, RFID allows manufacturing machines to identify and select the correct components for assembly, streamlining the production of finished goods.

Overall, the integration of RFID inventory management solution in manufacturing processes promotes efficient tracking and use of materials, leading to faster production cycles and better resource management, all while ensuring consistent quality.

ConnectPOS – Integrating RFID Inventory Management Solution for Optimized Operations

ConnectPOS is a powerful POS software that supports RFID inventory management solutions, tailored to enhance operations for businesses of all sizes. Its extensive features and smooth integration ensure precise and effective inventory management.

Key Features:

- Real-Time Inventory Tracking: ConnectPOS provides up-to-the-minute visibility into inventory, enabling businesses to monitor stock levels and locations with precision.

- Detailed Reporting: The system produces thorough reports and analytics, helping businesses make informed, data-driven decisions.

- Multi-Channel Integration: ConnectPOS seamlessly integrates with various sales channels, offering a unified view of inventory across different platforms.

- User-Friendly Interface: The intuitive interface is accessible to users with different levels of technical expertise.

- Scalability: ConnectPOS grows with your business, offering robust solutions for increasing inventory needs.

- Security Measures: The system includes features to safeguard against theft and loss, ensuring the protection of inventory.

- Customer Support: Dependable customer support assists users with any technical issues or questions, ensuring smooth operation.

Best Use Case

ConnectPOS is perfect for mid-sized to large retail businesses. It amplifies inventory accuracy and streamlines operations, making it an essential tool for businesses looking to improve their inventory management processes.

FAQs: RFID Inventory Management Solution

- Which Industries Gain the Most from RFID inventory management solution?

Industries with intricate supply chains, including retail, manufacturing, healthcare, and logistics, reap significant benefits from RFID technology due to its ability to streamline operations and improve accuracy.

- Is It Possible to Integrate RFID with Existing Inventory Management Systems?

Yes, RFID technology can be seamlessly integrated with existing inventory management systems. Companies like Lowry Solutions specialize in smooth, synchronized integrations that enhance system functionality without disrupting current operations.

- How Does RFID Technology Help Prevent Inventory Count Errors?

RFID technology helps prevent inventory count errors by providing real-time, precise tracking of items. It reduces the need for manual data entry, improves visibility, and offers instant updates, thereby minimizing discrepancies and enhancing inventory accuracy.

Conclusion

RFID technology is revolutionizing inventory management by boosting efficiency, cutting costs, and enhancing accuracy. As businesses increasingly adopt RFID, it is driving innovation in supply chain management and becoming a key element of modern inventory strategies.

Embracing RFID allows businesses to streamline operations and establish themselves as leaders at the forefront of technology. This dedication to efficiency and innovation is essential in today’s competitive market.

Ready to revolutionize your inventory management with ConnectPOS? Contact us today for a free consultation or project estimate.